Post courtesy Prudential Overall Supply

The term “cleanroom” has come to define a variety of spaces designed to control the level of airborne particles, temperature, humidity, and other environmental factors. These spaces are used in various industries, including pharmaceuticals, biotechnology, and electronics manufacturing, where maintaining a contaminant-free environment is essential for product quality and safety. While organization and cleanliness in any workplace is important, this is especially true for cleanrooms.

The basic premise of a cleanroom is that the airborne particulates are minimized to extremely low levels, and keeping these particulate levels in check is all about controlling the people and objects that come in contact with these rooms.

That means that supplies or people coming into a cleanroom can pose a risk of contaminating products being manufactured or treated, in a way that can cause irreversible harm that prevents them from functioning according to their intended purpose. Compromised products can be rendered useless (in the case of electronics) or unsafe (in the case of medical vaccines). And it is all too easy to cause this kind of destructive contamination.

Specific Items and Their Dangers

In cleanrooms, even minor, seemingly insignificant contaminants can compromise the integrity of processes and products. Therefore, it’s essential to be aware of the risks posed by common items that can trigger contamination, such as:

- Pens – Ink can leak, introducing chemicals into the cleanroom environment, and sometimes harbor mold.

- Pencils – Graphite and wood particles can shed, contaminating surfaces and air.

- Paper – Paper fibers can become airborne, carrying contaminants and disrupting cleanroom air quality.

- Personal Items – Jewelry, watches, and accessories can harbor skin cells and other contaminants.

- Cosmetics – Makeup particles can flake off, introducing biological and chemical contaminants into the cleanroom.

- Non-Cleanroom Approved Clothing – Fibers and particulates from regular clothing can contaminate cleanroom environments.

- Food and Drink – Particles and biological contaminants from food and beverages can severely impact cleanroom sterility.

- Electronic Devices – Heat generated by electronic devices can attract dust, and the devices themselves can emit particles.

- Cardboard Boxes – Fibers and dust from cardboard can shed and become airborne.

- Plastic Bags – Static electricity from plastic bags can attract dust particles and release them into the cleanroom.

- Staplers and Paperclips – Metal particles from these items can cause physical and chemical contamination.

- Adhesive Tape – Adhesive residues can collect dust and other particles, which can then be transferred to cleanroom surfaces.

- Fabric Materials – Non-approved fabrics can shed fibers and particles that compromise air quality and surfaces.

- Loose Hair and Skin Cells – Human biological contaminants, including hair and skin cells, can easily become airborne and settle on critical surfaces.

- Perfumes and Lotions – Volatile organic compounds (VOCs) from these products can off-gas, contaminating the air and surfaces.

- Footwear Not Designed for Cleanrooms – Regular shoes can track in dirt, dust, and biological contaminants.

- Writing Pads and Notebooks – Paper fibers and ink particles can be sources of contamination.

- Non-Antistatic Materials – Items that are not antistatic can attract and release dust particles due to static electricity.

- Non-Sterile Cleanroom Cleaning Supplies – Using cleaning supplies that are not approved for cleanroom use can introduce additional contaminants instead of removing them.

- Fabric-Covered Chairs – These can shed fibers and harbor dust and other particles that can become airborne.

Controlling these potential sources of contamination is vital for maintaining the strict air quality standards required in cleanrooms. One key way to do this is by mandating the use of clothing and accessories that are specifically designed for cleanroom environments.

Cleanroom Services and Supplies: The Basics

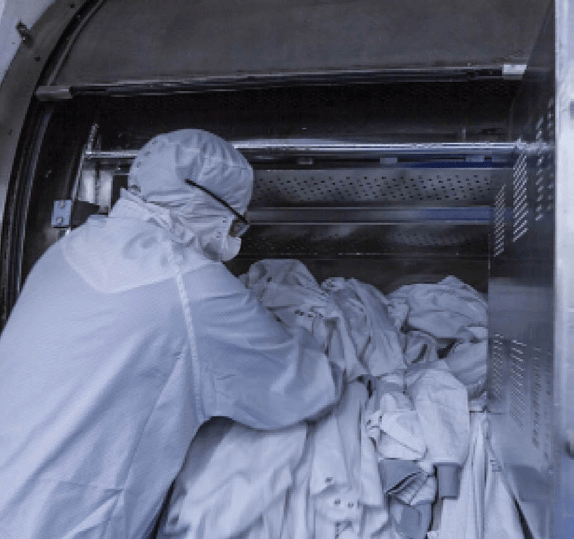

Work clothes in cleanroom environments must be able to control the contaminates that naturally and continuously emit from the human body. Cleanroom garments help contain the human skin flakes and oil that are naturally dispersed from our bodies at all times. These particles are not harmful in most situations, but in a cleanroom, they can compromise these highly controlled environments.

Cleanroom products and apparel are specifically designed to keep these contaminants at safe levels. Not only do these products help to manage contaminants, they are made of highly durable materials that, because they do not flake off or deteriorate, will not themselves add contaminants to the environment.

Traditionally, cleanroom apparel and cleanroom supplies were used once and then discarded. With advances in technology, cleanroom garments have been engineered to sustain multiple uses with proper cleaning procedures. For cleanroom garments, there are special protocols and procedures that companies must follow in order to ensure that their cleanrooms remain clean, controlled environments.

When selecting a cleaning service, you can check to see if they are ISO 9001:2015-certified as a cleanroom garment laundry service. Best practices for laundering cleanroom uniforms include keeping track of the number of times a cleanroom garment has been laundered and taking appropriate action when it is no longer suitable for use.

Nice short summary. Other key issues include outgassing incl for polyurethane foams, HEPA filter potting compounds and gel seals, sound deadening/vibration damping foam that can have organo Phosphorus compounds that can dope Si wafers with P. Garment cleanliness just before cleaning or gloves cleanliness new vs at end of use can be quite insightful since often much dirtier than when new. Consider where your gloves and especially cuffs of garments have been, since these are closest to products or parts. Also need to consider overall processes, such as IPA can be clean, dry glove or wiper contact with surface might transfer little contamination, but IPA wetting wipe and use of glove to wipe surface can extract much more organics from glove, permeate through wipe, and leave residues on clean surface like wafers, optics etc. We have a nice ESTECH Talk in 2006 on disposables that is work reading esp for semiconductor fabs. https://www.linkedin.com/in/markcamenzind/overlay/1607892978111/single-media-viewer/?profileId=ACoAAAE0F14BvXH8WrZWf_TtOvZYweXgeoVtFL0

LikeLike